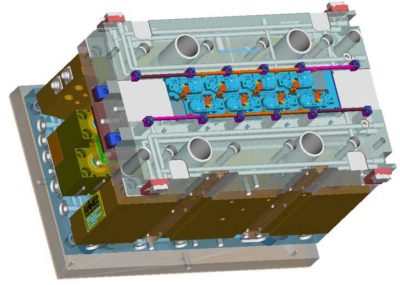

High-precision Molds

One of the core competences of our company is to design and build high-precision molds with state-of-the-art technical features, such as pressure sensors capable of detecting the injection pressure inside the cavity. Our molds are conceptualized and built in a manner that meets the requirements of the molded product. This is why we are able to guarantee the highest possible product quality throughout its product life.

Read more…

Reel-to-Reel

In the reel-to-reel process the end product is manufactured on a carrier strip. Upon completion of each manufacturing step, the carrier strip is wound onto a reel. Likewise, in the reel-to-reel molding, the strip carrying the molded product is wound onto a reel which, once full, is shipped to the customer for further processing. APINEX offers complete turn-key reel-to-reel molding systems. It is also possible to separate the parts from the carrier strip and then place them into suitable trays in order to facilitate subsequent manufacturing processes.

Read more…

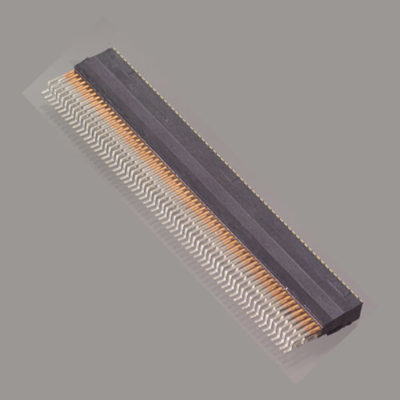

Insert Molding Technology

In the reel-to-reel process the end product is manufactured on a carrier strip. Upon completion of each manufacturing step, the carrier strip is wound onto a reel. Likewise, in the reel-to-reel molding, the strip carrying the molded product is wound onto a reel which, once full, is shipped to the customer for further processing. APINEX offers complete turn-key reel-to-reel molding systems. It is also possible to separate the parts from the carrier strip and then place them into suitable trays in order to facilitate subsequent manufacturing processes.

Read more…

High-precision Plastic Parts

We handle the mass production of high-precision plastic parts for the automotive, telecommunications, electronics, household appliances industries as well as the medical sector. For example, we employ state-of-the art production methods with high-speed handling robots. Instead of dropping off the mold, the molded components are picked, counted and packed by robot systems, separated by mold cavity.

Read more…

Microsystems Technology

The demand for small components in the industry increases as the mini end products all over the world win their popularity. Our wide experience and the continuous strive for the improvements make it possible to mold sophisticated, high quality and with the total weight of 1/1000g parts, with our up to 32 cavities, high precision tools. We offer you, based on your needs, an optimal, costs reducing but efficient production line with stable processes and evident means of controlling. Automatic production and packaging can be executed with clean-room technology for a small run or a million edition. A continuous quality control as well as a complete documentation is a standard for all our products.

Read more…

Components assembly

In our self designed assembly areas we are able to assemble plastic parts to complete end products or to just half complete sub assemblies, in small or big quantities. We offer enrichment processes, we work with your suppliers to offer you a complete solution for your products. Quality and cost effectiveness are our and your priority.

Read more…

Cleanroom Manufacturing for highest claims

For the manufacturing and packaging of plastic parts and components with the highest standards of cleanness, we have a clean room (clean room class ISO 8 according to EN ISO 14644) available for a controlled manufacturing environment. Air quality, temperature and air humidity are carefully matched. With fastidious cleanness criteria, contamination related waste can be avoided. This results in a positive impact on our product quality and economy.

Read more…