Mold Manufacturing

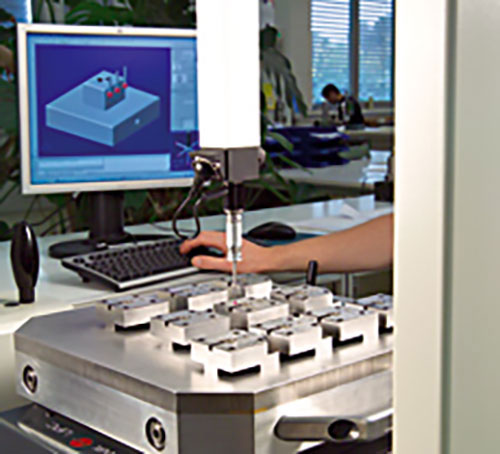

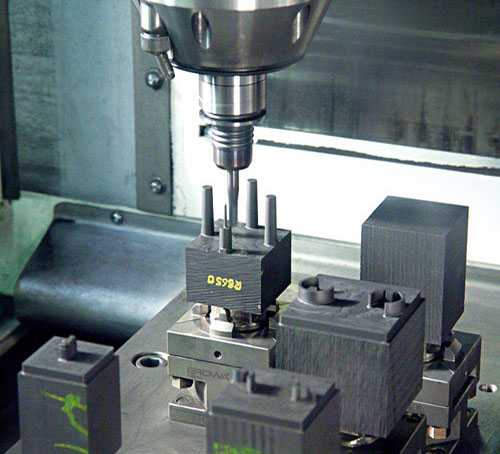

Our own tool room, fully air conditioned and equipped with state-of-the-art machine tools is in itself a center of competence. Drawings released for manufacturing are transferred directly to the CAM workstations through are internal network and from there are fed directly into computer & controlled machines.

Production samples coming off your mold are produced only after a full and successful quality inspection. This allows the definite assessment of the mold performance. The mold and all associated equipment undergo then large scale tests in pre production until finally the high internal and external requirements are met. After that, the project is released internally and is available for series production.

Naturally, we possess most modern measuring equipment; our tool shop is as well fully integrated into our management system, entirely controlled and monitored by our project management and ERP System.

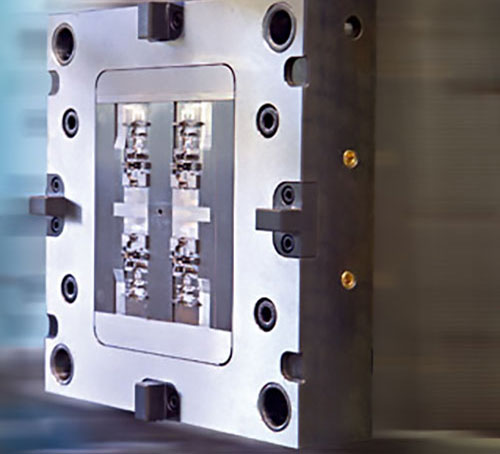

High precision tools

One of the core competencies of our company is to design and build high-precision molds with state-of-the-art technical features such as pressure sensors capable of detecting the injection pressure inside the cavity. Our molds are conceptualized and built in a manner so as meet the requirements of the molded product. This is why we are able to guarantee the highest possible product quality throughoust its product life.

Should you have any questions or require further information, please do not hesitate to contact us directly.